News: April 22th, 2008

Our company has just completed successfully installation and commissioning a CNG filling station in Uzbekistan in April 18,2008,This first CNG filling station was built by Chinese company in Uzbekistan.

Introduction of CNG Project

Nowadays because of the contradiction of supply and demand of fuel and the increased harm vehicle tail-gas does to the environment, it is urgent to find some ways to solve this problem. And as we know natural gas has many advantages such as good antiknock quality, high reliability, less harmful pollution, low cost, etc. and it can also prolong the service life of vehicle engine and motor-oil. Natural gas has become an ideal and high quality vehicle gas. Consequently, CNG vehicle became an important means to solve the problems of both energy sources and environment.

This series CNG is the very product based on the international situation. It is an environment protection product of high technology. Its technology is in leading position in China. Also its technology data has approached international advanced level and the price is competitive to the European countries. We could provide the CNG refueling station complete equipment and turn-key project with advanced technology, reliable quality, reasonable price, good service for the markets abroad.

Now the rate of market possession in China is very high and the products have been exported to countries in Asia and so on.

Introduction of Equipment

1. Suction system

Suction system consists of pipe pressure adjusting device, suction buffer filter and so on. Pressure adjusting device is used to adjust suction pressure.

Suction buffer filter is used to buffer gas, steady suction pressure, reduce gas pulse, and remove impurities in gas to protect system equipment.

2. Sweetening system

If the content of H2S in natural gas is move than 15/Nm3, the gas should be desulphurized by chemical way. Usually the desulphrization includes two desulphrization tower,one humidifier, desulphrizer and so on. Of course if the content of H2S is less than 15mg/Nm3, this equipment is not necessary.

3. Control system

Control system is auto-control equipment. The system can control the on-line operation of compressor and accessory equipment through computer or PLC, and provide relevant safety protection (e.g. suction pressure, each stage discharge pressure, lubrication oil pressure, cooling water, temperature, etc.)

4. Waste gas collecting system

Waste gas collecting system is mainly natural gas tank. The system recovers waste gas of compressor into suction system for reducing natural gas waste.

5. Cooling system

The system consisting of water pump, cooling tower, valve, is used to cool water-cooled natural gas compressor. In order to remove scale, the cooling system shall be equipped with electric water treator. The specification of cooling system depends on compressor type and quantity. The cooling tower is not needed if the natural gas compressor is cooled by air of air-water mixture.

6.High pressure dewatering device

Rear treatment system is mainly the high-pressure regenerative dryer, which dry and purify the high-pressure gas after compression. It ix also one of main accessory equipment for CNG filling station and consists of separator, filter, oil eliminator, cooler, heater, pressure reducing device and so on.

7. Gas transportation control system

The pressure difference between cylinder cascades and vehicle cylinder directly affects filling time. The system can keep the best filling speed for vehicle.

The system mainly is program control panel. We can provide manual and automatic program control panels.

8. Cylinder Cascades Storage

The system is used to store compressed high pressure natural gas to save filling time. The system has three groups for high pressure, middle pressure and low pressure. The gas may be stored in two ways: cylinder cascades and gas well.

9. Dispenser

The system can measure the compressed natural gas filled into high-pressure cylinder of natural gas vehicle. There are two dispenser types: digital single hose and digital dual hose natural gas dispenser.

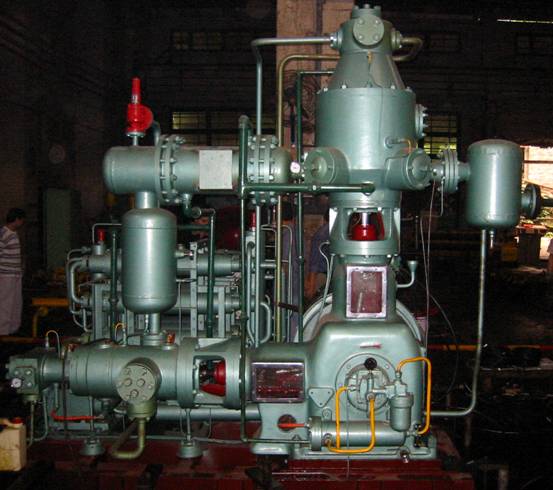

10. Compressor

A. L-type series natural gas compressor

The series compressor is of L type, water-cooling, stationary reciprocating piston. It's cylinder is lubricated with less oil, discharge capacity is 25Mpa, gas supply is fitted with PLC for automatic control and protection. The compressor is of whole package on skid, low speed, stable running, low vibration, low noise, applied to big and middle filling station.

W-type series natural gas compressor

The series compressor is of W type, 4 stages or 5 stages compression. It' s cylinder is lubricated with less oil, discharge capacity is 25Mpa, gas supply is 200~1200Nm3/h. The compressor is fitted with PLC for automatic control and protection and cooled by water or mixture mode. As whole package on skid, it is of compact structure, easy installation and maintenance, especially applied to the places where water is lacking. W-type, 5-stage compressor is designed specially for area where temperature is high and pipe pressure is low.

|